News

当前位置:Home > News > Industry news >

Three changes to help PCB enterprises to implement green pro

发布时间:2016-08-17 20:58

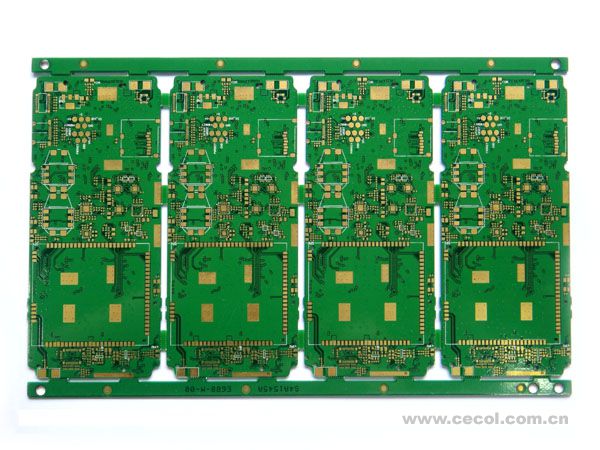

As a result of green production involving the entire product materials, production processes, production equipment, production environment and production management, etc., so PCB manufacturing must be in the concept, technology and management to change.

Green production refers to the goal of saving energy, reducing consumption, reducing pollution, taking the management and technology as the means, the implementation of the whole process of industrial production pollution control, so that the amount of pollutants produced at least a comprehensive measure. As a result of green production involving the entire product materials, production processes, production equipment, production environment and production management, etc., so PCB manufacturing must be in the concept, technology and management to change.

Change ideas to adapt to the situation

We should be good at to accept new things and new changes, production is not only production of qualified products, but also to used in accordance with the materials required for green products, and to achieve energy-saving, water-saving, zero emission or less emissions, in a clean environment to produce environmental protection, improve the efficiency of resource of green products. Material change, production process and equipment renewal, environment improvement, waste and wastewater treatment improvement, in the short term will bring the increase of production cost, and large amounts of capital investment, but the benefits are not immediately visible and is uncertain. In addition, the material, production technology and detection technology changes will have an impact on the original management system.

Technological change to improve product quality

Improve the existing process and develop new technology to improve the product qualification rate, reduce scrap, improve product quality and prolong the life cycle of the product.

Make full use of raw materials, improve the utilization of resources and energy, minimize the waste of the production process, reduce the pollutant emissions in the production process, and improve the efficiency of production.

Simplified product processing process, reduce the processing procedure, reduce waste of resources and pollutants in the process of manufacturing, using than conventional method can significantly save energy technology and equipment, such as the use of direct plating of short process instead of traditional electroless copper plating process and chemical treatment of water by two or three levels increased to three or four, use the working solution has the advantages of small volume, less heat loss of the level of equipment, the high efficiency of heating circulation and filtration equipment and so on.

The application of the new technology should replace the original process of containing toxic substances, as well as the corresponding process and process of lead-free soldering. To provide a pleasant working environment, conducive to the physical and mental health of employees, is conducive to improve work efficiency and product quality, reduce the occurrence of safety accidents.

Strengthening of generated in the production of the three wastes (waste water, waste gas and solid waste) control, recycling and reuse and for raw materials in situ reuse, especially in the process of recycling. Such as PCB wastewater treatment and reuse: copper etching solution to implement the "zero" emissions containing, can avoid from the PCB etching down accounted for about 70% of the copper foil copper containing waste liquid to sell specialized recycling of copper processing field and serious "secondary pollution, and recovery of copper from the" zero "emissions, which is to reduce or avoid the key measures of copper pollution. And as the recycling of waste and scrap: the PCB (including CCL, copper clad laminate) in the production process of bits and pieces together by mechanical physical method by crushing, sorting, crushing, recycling and other processing, respectively, to obtain the metal fragments (for recovering metal and non metal powder, as a filler is added to the all kinds of plastic products and architectural coatings.

To improve process control, transformation of the original equipment, the raw material consumption, waste, energy consumption, health and safety risk and ecological damage reduced to a minimum, the maximum to avoid or reduce the harm to the human body, such as electromagnetic radiation, noise, toxic gases,